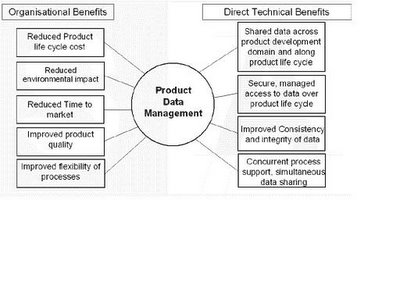

There are nine basic components of an EDM/PDM system. The first of these is the Information warehouse in which engineering information is stored.

The Information warehouse is managed by the Information management module. This is the second component of the EDM/PDM system. It controls and manages the information in the warehouse. It is responsible for functions such as data access, storage and recall, information security and integrity, concurrent use of data, and archival and recovery.

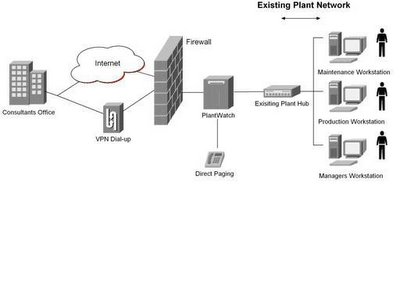

The EDM/PDM system requires a basic Infrastructure of a networked computer environment.

Users and programs access the system through the Interface Module. This provides a standard, but tailorable, interface for users. The Interface Module supports user queries, menu-driven and forms-driven input, and report generation. It provides interfaces for programs such as CAD and ERP.

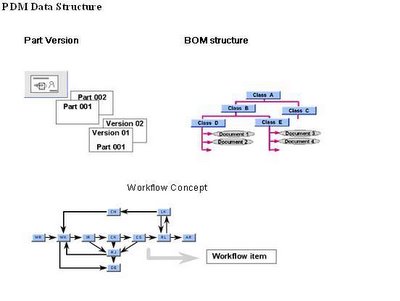

The structure of the information and processes to be managed by the EDM/PDM system is defined by the Information and Workflow Structure Definition Modules. The workflow is made up of a set of activities to which information such as resources, events and responsibilities can be associated. Procedures and standards can also be associated with activities.

The exact structure of all information in the system is maintained by the Information Structure Management Module.

Once initiated, workflow needs to be kept under control. This is the task of the Workflow Control Module, which controls and co-ordinates the engineering process. It manages the engineering change process and provides revision level control.

The ninth component of the system is the System Administration module. The complete system is under its control. It is used to set up and maintain the configuration of the system, and to assign and modify access rights.

The Information warehouse

The role of the Information warehouse module is to store engineering data. Other names for the warehouse are Electronic Library, Electronic Vault, Information Vault, and Data Repository.

The Information warehouse acts as a single source of all engineering information in the company. This does not mean that the information has to be physically centralized. In practice it will nearly always be physically distributed, with some of the information being in different departments of the company, and some with suppliers and customers.

The Information warehouse contains all sorts of engineering information describing the products and parts such as engineering drawings, CAD data, circuit layouts, flow charts, test results, Bills of Materials, field data and word-processed product specifications. There will be information such as NC programs and technical manuals describing the processes used to design, manufacture and support the product. There will be information describing international, national and company-specific standards. There will be information describing the computer programs used in the various processes, and there may even be copies of these programs in the warehouse. There will be project-specific and order-specific information starting perhaps with the contract, and including project time and cost estimates, and actual times and costs.

The Information warehouse will contain information about information. There will be lists of drawings, parts and configurations. There will be descriptions of more complicated relationships such as those between the activities of a particular project to fulfill the requirements of a particular customer order. There will be information such as Engineering Change orders, describing changes to information in the warehouse.

Information Management

Engineering data is kept in the Information warehouse, a logical store of all engineering information on all media at all locations - centralized and distributed. The Information management module controls access and input to the Information warehouse.

The Information management module controls the input and output of data to and from the Information warehouse. It works in a multi-vendor distributed computer environment, and is able to control access to different types of data such as text files, CAD geometry, engineering drawings, and numeric results of technical calculations. It manages data in simple files, and in hierarchical, relational and object-oriented databases. The data can be in private databases (single-user), project databases (multi-user, linked to individual projects) and product databases (multi-user, describing parts and components).

The module uses metadata (data describing data) to manage data. Most of today's EDM/PDM systems are based on relational database management systems. Only the metadata (containing characteristic information about the underlying data, such as file name, type of data, author, location, access rights, version number, cost, date and other attributes), a small part of the engineering data, is stored in the relational database. The underlying engineering data is stored in the system where it was created.

The Information management module is aware of the various stages of the life cycles of the different information types. It knows how they are created, how they are used and modified, how they are stored, and how they are archived. It knows the possible release and revision levels of documents, and the steps they go through to be signed-off, released and changed.

The module is aware of the potential users of the system. Typical users include design engineers, drafters, manufacturing engineers, shop floor workers, project managers, cost analysts, and procurement staff. Users may be in different functions or at different locations of the company, or on supplier or customer sites. The module is aware of the activities and privileges of each user. It can handle situations where users have more than one activity, and where users have different roles on different projects.

The Information management module has complete control over access to the Information warehouse. It uses access rights to control user access to information items throughout the various stages of product and project life cycles. Access rights allow access to be controlled by a variety of criteria such as user, product, project, group, device, type of information, and state of information. Different access rights can be assigned to a user for activities such as creation, selection, view, modification, release, report, translation, archival, and communication of information.

The module is aware of all information in the warehouse, all activities that can be carried out on the information items, all users of the system, and the rights of all users to carry out particular activities. As a result it can control access to all information in the system. The Information management module allows users with suitable authorization to check individual files or sets of files into the warehouse, and to check them out. Sets of files may be related by different parameters such as document type, product, and user.

The Information management module is responsible for the security of information in the system. Security can be applied at different levels and on different categories such as per-user, per-information item, per-activity, or per-product. The module only provides access to authorized users, and refuses access to unauthorized users. It provides security information on any unauthorized attempts to access data. The module can provide an audit trail of all actions taken on data. The audit trail can show who has accessed and changed both data and metadata.

The Information management module is responsible for the integrity of the warehouse. It prevents multiple simultaneous update of information. It informs users of copies of information when master data or metadata has been modified, and can send them up-to-date copies. The module can manage the back-up and archival of data. It can recover any information lost as the result of computer or human problems.

The module can use metadata items as search criteria. It can search for the existence, location and status of particular information on the basis of pre-defined classification codes and characteristics such as physical properties, manufacturing processes, and part numbers. It can use metadata items for information browsing and navigation.

The Information management module can maintain distribution lists based on its knowledge of the users of the system, and the documents in the system. The lists can be dependent on specific characteristics such as current project status.

Infrastructure

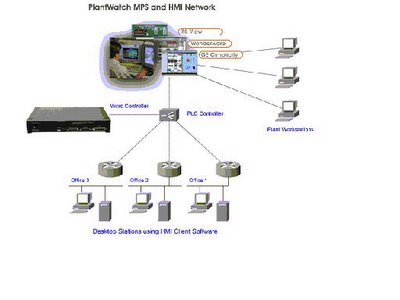

The Infrastructure module provides the basic system functionality for the EDM/PDM system to operate in a multi-application, networked, heterogeneous computer environment.

Typical engineering environments include all sorts of computers, file servers, workstations, X-terminals, PCs and other graphics and alphanumeric terminals from many vendors. There will be a variety of operating systems, some of which will be proprietary. Others will be more-or-less standard versions of DOS and UNIX

The environment will probably include a wide range of application packages and in-house developments for order processing, parts management, configuration, MCAE, CAD, ECAE, ERP, document scanning, electronic publishing, structural analysis, process planning, project management, word processing, and field support

In the typical environment, there will be a variety of peripherals such as scanners, printers, plotters, shop-floor terminals and data storage devices. Much of the electronic data will be on simple files, but some could also be in hierarchical or relational databases (such as INFORMIX and ORACLE), or in other engineering data management systems. The information and its users will be distributed over different departments, different sites, and perhaps different companies.

Servers and workstations will probably be connected by WANs (Wide Area Networks) and LANs (Local Area Networks) so that information can be communicated both between sites and on-site. There will probably be links to the Internet, Intranets and the Web. There may be electronic links to suppliers. Both long 'files' and short 'messages' will have to be communicated on the networks. A file transfer of a CAD model to a supplier may involve the transfer of several MB of data. Many EDM/PDM systems rely heavily on electronic messaging to inform interested parties that a particular 'event' has occurred, and that work on the following task should now be started. For example, a message could inform a supervisor that a design has been completed and can now be released. Such messages may only be a few words long. Notifications through electronic mail ensure that everybody who needs to be aware of what is happening receives the information, and that everybody is involved in a timely fashion. In this way, when it is not possible to physically co-locate all members of a project team, the system helps create a virtual team